Our webstore uses cookies to offer a better user experience and we recommend you to accept their use to fully enjoy your navigation.

New Chemical Techniques

Barrel polishing is a dry treatment process which makes it possible to obtain mirror-polished finish for many parts made of plastic and natural materials such as mother-of-pearl or horn.

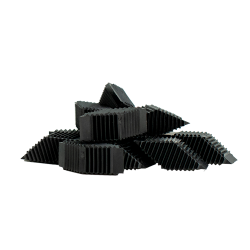

The process consists of placing the pieces to be polished in higgledy-piggledy in rotating barrels which contain small wooden sticks previously coated with abrasive paste.

This technology, which is particularly profitable, is mainly used by the polyester, mother-of-pearl and corozo button industry, by users of cellulose acetate (headdress ornaments, pawns, handmade glasses frames, etc.), by high-end fantasy jewelry manufacturers, or even by the manufacturers of horn

knife handles.

.png)

Small containers

Take advantage of TCN products in small formats for all your needs.

Logs

To obtain a satisfactory end result, it is important to take into account several elements such as the size, shape and quality of the logs, as well as the level of abrasiveness of the pastes used. These factors are crucial to ensure effective polishing.

Polishing pastes

By using the appropriate polishing paste and following several successive polishing steps, it is possible to eliminate surface defects such as joint lines and scratches on the pieces. This process makes it possible to obtain satin or gloss finishes depending on the needs and preferences.

Oils & Detergents

In order to remove oils and grease from the surface of polished parts, it is necessary to carry out specific cleaning.

Glues, resins & hardener

Handmade spectacle frames are made differently from conventional frames. Our goal is to help manufacturers produce quality frames by offering them specific glues for assembling cellulose acetate. We offer cold and hot glues to meet the needs of our customers.